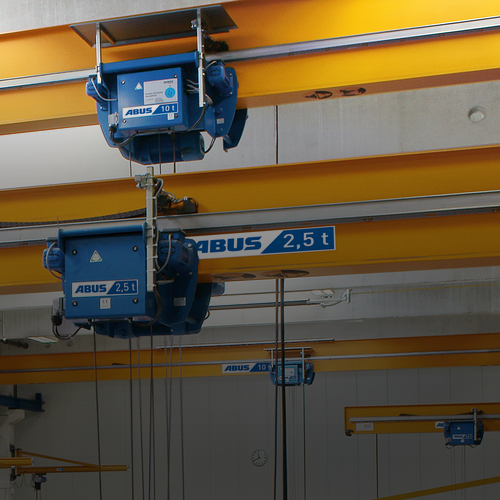

ABUS EOT crane at an automobile industry supplier

The pioneers of the German automobile industry such as Gottfried Daimler and Carl Friedrich Benz developed, constructed, and built the first cars almost single-handedly. Only very few components were supplied. However, the giants of modern automobile production rely on several hundreds of suppliers delivering individual parts or sophisticated subassemblies just in time to incorporate them into the production processes. The percentage of subcontracted supplies for automobiles amounts to about 75% nowadays. Suppliers may be small or middle sized companies or they may be big international groups. Examples for these international suppliers to the automobile industries would be found in Lippstadt, a town in Westphalia: the company HELLA specialises in lighting technology involving all areas concerned with headlights and lighting, and the company BHTC is busy in the field of automotive climate control.

Forthaus – competence in specialised machinery and jigmaking for automobile industry suppliers

For their production processes, HELLA as well as BHTC rely on highly qualified suppliers in the area of specialised machinery and jigmaking. These suppliers established themselves around the automobile industry in the eastern parts of Westphalia. One of them is the company Forthaus (www.forthaus.com) at Langenberg, founded in 1990 to develop and to produce jigs and rigs for the assembly of headlights and climate control devices in their different building stages. Forthaus also makes mounting fixtures for the metallisation and painting of components, press-in machines, and jigs for measurement and test engineering. For the production of headlights HELLA uses for example vapour coating drums, carriers with receptors for the vapour coating of reflectors, and devices allowing to calibrate and grade lamps according to light intensities. A team of thirty staff including six construction engineers handle the whole production process from the first enquiry and individual assistance right through to the delivery and installation of the jigs. Training and service on site is also part of the services on offer. Forthaus uses several CNC machines in their own production hall including 3-axis and 5-axis milling machines, and they also have their own electrical design department. The application photo shows a typical bespoke press-in machine.

The ABUS EOT crane as a solution for transport within the production

Forthaus is using an ABUS EOT crane for the internal material handling and the transport of individual components to the different machining centres: a single girder EOT crane of the ELV type with a lifting capacity of 5 tonnes and a span of 9.77 metres. The hoist used is an electric wire rope hoist, type GM 1000. The single girder trolley is characterised by a compact design and very favourable building dimensions and is generally the most frequently used hoist for lifting capacities up to 16 tonnes. The crane is controlled via push button pendant with mobile control along the main girder.